The Direct Air Capture Microprocessor - Innovating DAC from the Inside Out

Most direct air capture companies are trying to build the best mouse trap they can with capture materials that are readily available. Jeevan has re-invented the “microprocessor” that powers carbon capture and is innovating its technology starting from that core and working outwards.

In this video Jeevan COO, Steve Siegel, explains how Jeevan is innovating direct air capture technology from the reverse angle of many existing players in the space.

A lot of the direct air capture companies on the market are trying build the most efficient and cost effective product using materials that are out there and readily available. And there is plenty of innovation happening in the field that is encouraging in service of

But generally, it's about “how can I build the best mousetrap with the materials that are available.”

At Jeevan, we've done it from the reverse.

We developed the core capture material first (a new class of solid sorbent amine resin called DeCarbonHIX) and we’re engineering machines that make the most of this game-changing medium. Siegel likens it to the microprocessor (the core technology of a computer).

Once you develop a core technology that is 4 times faster than everybody else's, and uses less energy, and you can integrate it into a machine that is built to optimize the use of that material, you have a distinct advantage over everybody else.

Click here to hear more about our technology from our leadership team or contact us if you’d like to find a way to work together.

Turning the Tide on Brine: Energy-Efficient Breakthrough in Industrial Wastewater Treatment

Jeevan researchers unlock a critical new method of dealing with hypersaline brine.

SUMMARY

Published today in a peer reviewed paper in Nature Water, Jeevan Founder and CEO, Dr. Arup SenGupta, and Jeevan Lead R&D Engineer, Dr. Hao Chen, demonstrate an Evaporative Ion Exchange (EIX) process to concentrate hypersaline brine, a salty industrial byproduct from processes like fracking.

The study was completed with grant funding from the US Bureau of Reclamation, the Pennsylvania Infrastructure Technology Alliance, and a Lehigh faculty innovation grant.

Unlike traditional methods, EIX requires little energy and operates at room temperature. The process uses ion exchange resins that absorb water, which then evaporates when exposed to air. It can crystallize salts like sodium chloride and barium without clogging the resin, offering a more efficient way to manage and potentially reclaim valuable resources from industrial wastewater.

ABOUT THE STUDY

The process works in two steps:

First, when the brine touches the dry resin, water from the salt solution moves into the resin, causing it to swell.

Then, when the swollen resin is exposed to dry air, the water evaporates, and the resin shrinks.

The EIX process was tested on synthetic hypersaline brine and water from Marcellus Shale gas wells. The Marcellus sample included high levels of salts and minerals like barium and calcium. After several cycles, the process significantly reduced brine volume and increased salt concentration, leading to the crystallization of barium chloride and sodium chloride without resin fouling. The process also showed potential for recovering lithium from brine.

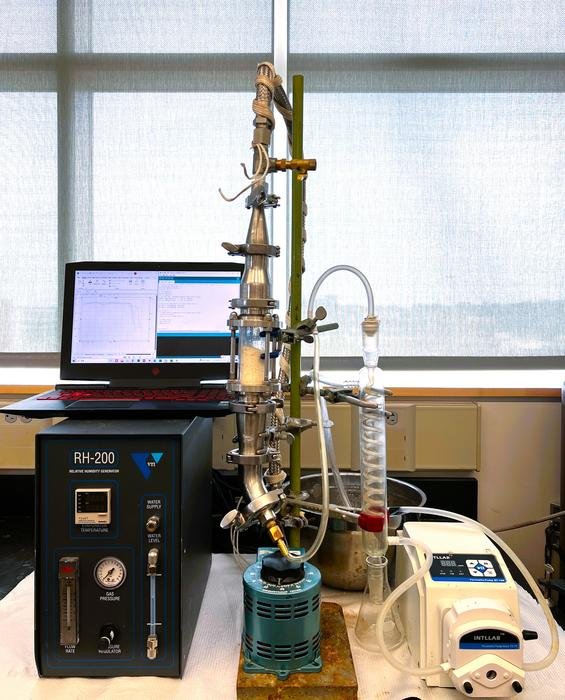

Photo of experimental device created by Dr. SenGupta and Dr. Chen.

REAL WORLD APPLICATIONS AND NEXT STEPS

Current methods of dealing with hypersaline brine often exacerbate environmental harm. Some coastal desalination plants pump brine into oceans, disrupting ecosystems, while inland facilities use inefficient evaporation pools, which can contaminate groundwater. This new discovery could help mitigate that damage.

Dr. SenGupta is optimistic about the prospect of scaling the technology as it does not require any specialty material and does not need any heat or major energy source.

If you’d like to learn more, contact us or follow us on LinkedIn.